Baxter Badure says that making saddles was a craft born of necessity.

“I’m not a good bronc rider but I’ve rode enough of ‘em,” he said. “The right saddle can really make a difference.”

Badure was a young hand working on the Triangle ranch in the Nebraska Sandhills when he purchased a saddle built by famed South Dakota saddle-maker Jerry Croft. It cost him $3,000, and, he said, “I only made about $6,000 a year in those days.”

The Triangle used only horses for all of their cattle work and would run a wagon for spring brandings and fall roundup. “We were way out there in the middle of nowhere,” Badure said.

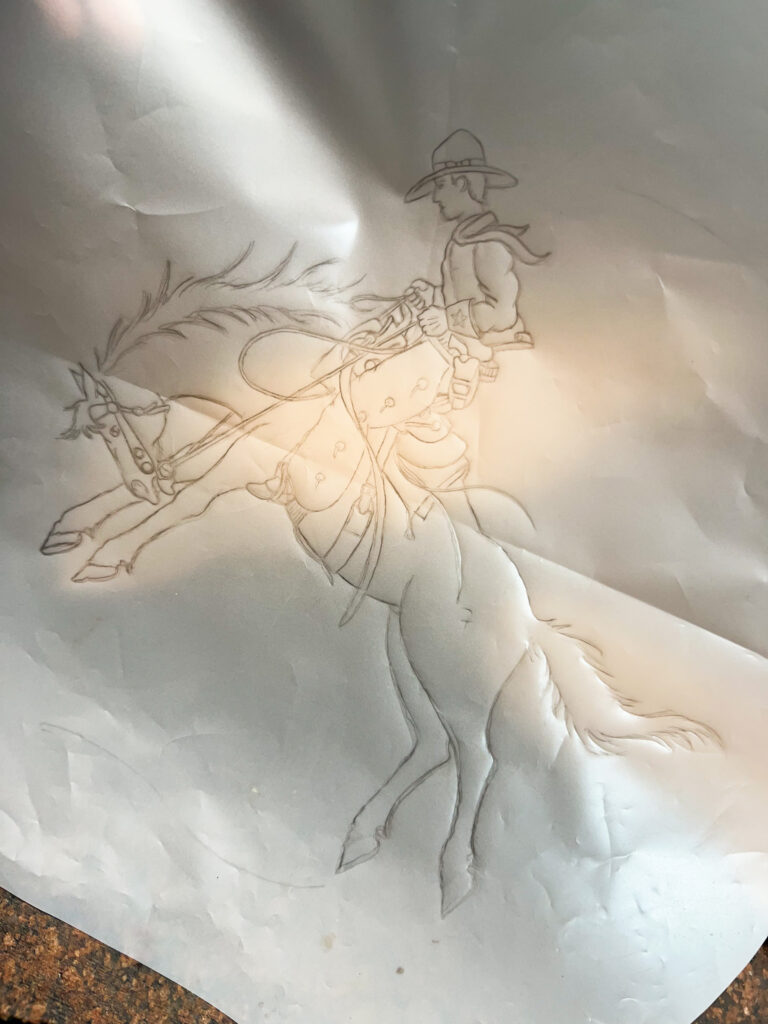

Drawing pictures and doing leatherwork laid a foundation for the ornately tooled—with intricate designs made by hand—saddles Badure is now known for making.

BAXTER BADURE“If you build your own saddle, you can get just what you want. It may not be perfect the first time, but you can always take it apart and rebuild it.”

“When I spent the evening in the bunkhouse I laid on my bedroll and drew pictures of bronc riders and stuff, we didn’t have TV,” Badure said. “I always could draw a little bit. I like to make my saddles heavily tooled.”

Inspired by the saddle he bought from Croft, Badure started building saddles on his own. He took apart saddles to see how they were put together, read books, studied saddles in museums, and looked at other people’s work.

“Jerry Croft helped me out a lot when I started,” Badure said. “He gave me a list of stuff I needed.”

Croft learned his trade from R.C. “Bob” Fox after purchasing Fox Saddlery in Belle Fourche, South Dakota, in 1975. He went on to build over 1,000 saddles, including saddles for Tom Selleck’s westerns, starting with Quigley Down Under.

Badure’s saddles are built for riding in rough country, designed to make long hours in the saddle comfortable and safe for horse and rider. Aspects of historic Miles City, Hamley and Visalia saddles as well as Croft’s saddles have all been incorporated into Badure’s design.

“When I built my first saddle I didn’t know a nice seat wrap from a bad one but it rode good,” he said. “I have used whatever I find eye appealing from other saddlemakers and blended pieces of their styles together into my own. Over time you get your own style.”

He is happy to customize the seat for each customer, but he said that he sticks to ranch saddles.

“I build a saddle that will function out on the ranch,” he said. “This is the style I’ve always used, and the kind of saddle that the people around me ride. In this country, when we take off in the morning, we might trot a horse for 30 miles in the day. We might need to rope a bull. We need a saddle that won’t gall a horse and one that will withstand the strain of holding that bull.”

Badure says that it may take him three years to build a saddle. He has his workshop set up in the basement, and works on projects after putting in a full day of ranch work.

“I’m pretty slow,” he said. “I don’t have a sewing machine either, so I’m limited to what I can do with my hand tools.”

Currently ranching near Belvidere, South Dakota, Badure has made 90-some saddles since he started, mostly for friends and neighbors. He has also built a special saddle every year since 2000, commissioned by the Ranchers-Cattlemen Action Legal Fund United Stockgrowers of America (R-CALF USA)—a non-profit organization that represents U.S. cattle and sheep producers on domestic and international trade and marketing issues. R-CALF USA’s membership consists primarily of cow-calf producers, cattle backgrounders, and feeders, many of whom spend time in the saddle on a regular basis.

“Baxter’s commitment and dedication is a real blessing; it is unprecedented to have one person who has been that devoted and committed to this organization in such a meaningful, artful way,” said Bill Bullard, R-CALF CEO. “He’s a true artist, and his contribution to us is priceless.”

Badure is still finding new challenges with each project, and says, “You learn things as you go. Every time I tool another flower, I try to make it turn out better than the last one.”

Badure also builds various other cowboy leather gear, including batwing chaps and old style bridles. He looked at historical photographs to build himself a pair of Angora chaps to wear when he rides in the winter. He has also built buckskin gauntlets, which his wife decorated with beadwork.

Still, he says, building saddles is a nice little hobby.

“If you build your own saddle, you can get just what you want,” Badure said. “It may not be perfect the first time, but you can always take it apart and rebuild it.” He does feel that it’s important to be able to criticize his own work, and says, “I show people where I screwed up.”

Badure said that he had an incredible response to pictures of last year’s R-CALF saddle that his daughter shared online. He knows there’s a market out there for his saddles if he chose to spend more time building them.

For now, he prefers to stay in the saddle.

“I’m not so old and decrepit yet that I need to build saddles full time,” he said. “I’ll keep chasing cows for a while.”